1. Check quantity variance between ASN and Receive

WMS will check quantity variance between ASN and generated Receive document during posting receive process. If there is any variance found, WMS provides an option to let user saves the information into Receive's Remark. (Refer to Image 1.a and Image 1.b)

3. Notify day to expiry when posting Issue

(a) In order for WMS to trigger this notification, user have to first set up the setting in Customer Item. (Refer to Image 3.a)

WMS will check quantity variance between ASN and generated Receive document during posting receive process. If there is any variance found, WMS provides an option to let user saves the information into Receive's Remark. (Refer to Image 1.a and Image 1.b)

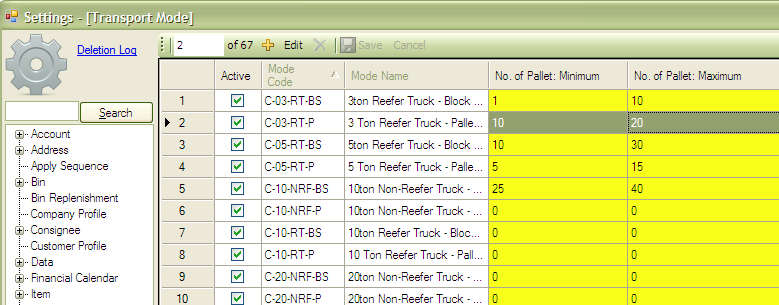

Image 1.a

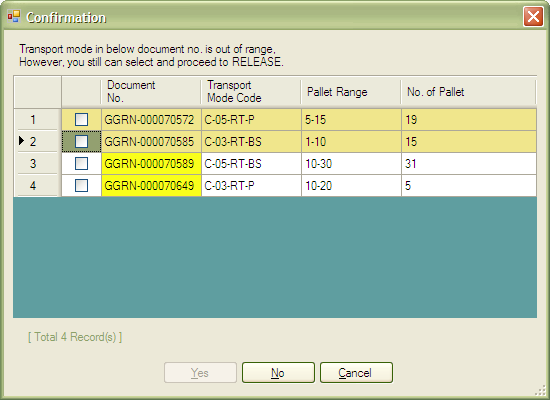

Image 1.b

2. ASN Summary

A new summary screen has been added in Advanced Shipping Note (ASN) module. (Refer to Image 2.a)

Image 2.a

(a) In order for WMS to trigger this notification, user have to first set up the setting in Customer Item. (Refer to Image 3.a)

Image 3.a

(b) During posting Issue document, WMS compares expiry date of each selected records with the number of day(s) to notify setting in customer item. If any criteria matched, WMS prompts a dialogue form for user to choose whether still proceed to post even though selected record is nearly expired or already expired. (Refer to Image 3.b)

Image 3.b

4. Stocktake module

A new module has been added to facilitate the stocktake processes.

Fixed Bugs:

1. Error occurs in Update Issue Header Info.

2. Error occurs in filter source code in Request of Transport.

2. Error occurs in filter source code in Request of Transport.